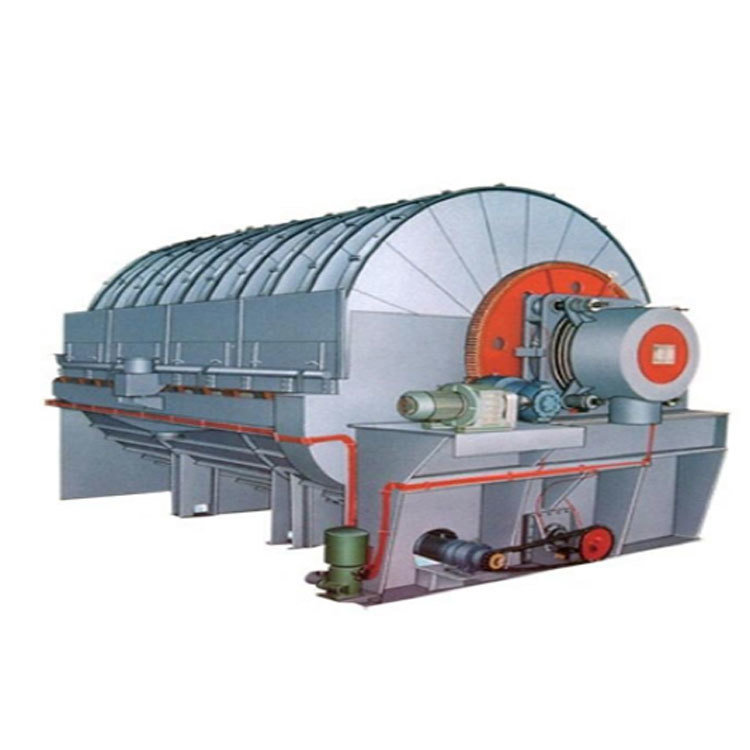

150ZGB series slurry pump

Slurry pumps belong to centrifugal pumps in terms of working principle. Conceptually, they refer to a kind of machinery that increases the energy of solid and liquid mixed media through the action of centrifugal force

- Commodity name: 150ZGB series slurry pump

- Commodity ID: cp5102

- 产品描述

-

Product description

Slurry pumps belong to centrifugal pumps in terms of working principle. Conceptually, they refer to a kind of machinery that increases the energy of solid and liquid mixed media through the action of centrifugal force (rotation of the impeller of the pump), and converts electrical energy into Kinetic and potential energies of the medium of the device. Mainly applicable to: mines, power plants, dredging, metallurgy, chemicals, building materials and petroleum industries. The name of the slurry pump is a kind of centrifugal pump divided from the perspective of conveying medium. In addition, the slurry pump can be divided into different types from different angles. In addition to pumping water, the water pump can also pump gas, solid, solid-liquid mixture - mineral powder mud! The power consumption of water pumps accounts for a large proportion of the country's total electricity, and the energy saving of water pumps has an important impact on the national economy. Water pumps not only It plays an active role in the energy-saving link, and also plays an important role in the process of thermal power generation emission reduction. The slurry pump not only saves energy by 4%-8% compared with similar products, but also contributes to the escape of the atmosphere from the "magic claws" of smog.

Working principle

First, let’s talk about the relationship between the centrifugal pump and the slurry pump, and then the principle of the slurry pump will be naturally clear. The centrifugal concept is based on the pump principle. There are many kinds of pumps, which can be divided into dozens of categories according to different angles. The centrifugal pump is divided from the working principle of the pump, which is the process of pressurizing the conveying medium through the action of centrifugal force. In addition, there are common types including screw principle, plunger principle, etc., which can be divided into pumps that are different from centrifugal principles. After talking about the concept of centrifugal pumps, let’s talk about slurry pumps. Slurry pumps are divided from another angle, that is, from the conveying medium. As the name implies, the slurry pump transports a mixture of solid particles containing dregs and water. But in principle, the slurry pump is a kind of centrifugal pump. The main working parts of the centrifugal pump are the impeller and the casing. The impeller device in the casing is located on the shaft and connected with the prime mover to form a whole. When the prime mover drives the impeller to rotate, the blades in the impeller force the fluid to rotate, that is, the blades do work on the fluid along its moving direction, thereby forcing the pressure potential energy and kinetic energy of the fluid to increase. At the same time, under the action of inertial force, the fluid flows from the center to the edge of the impeller, and flows out of the impeller at a high speed, enters the extrusion chamber, and then is discharged through the diffusion tube. This process is called the water pressure process. At the same time, because the fluid in the center of the impeller flows to the edge, a low-pressure area is formed in the center of the impeller. When it has enough vacuum, under the action of the suction end pressure (generally atmospheric pressure), the fluid enters the impeller through the suction chamber. This process is called Water absorption process. Due to the continuous rotation of the impeller, the fluid is continuously discharged and sucked, forming continuous work. The working process of centrifugal pumps (including slurry pumps) is actually a process of energy transfer and conversion. It transfers the mechanical energy of the high-speed rotation of the motor through the blades of the pump and converts it into the pressure energy and kinetic energy of the pumped fluid.

Work purpose

Slurry pumps can be widely used in mines, electric power, metallurgy, coal, environmental protection and other industries to transport slurry containing abrasive solid particles. Such as slurry transportation in metallurgical beneficiation plants, hydraulic ash removal in thermal power plants, coal slurry and heavy medium transportation in coal washing plants, dredging of rivers, dredging of rivers, etc. In the chemical industry, some corrosive slurries containing crystals can also be transported. First of all, in the application of mineral processing plants, about 80% are used in mineral processing plants in the mining industry. Due to the harsh working conditions of primary ore separation, the service life of slurry pumps is generally low in this section. Of course, different ores have different abrasiveness. If the relative abrasiveness is reduced in the process of concentrate transportation, the overall service life of the pump will be longer. Therefore, when general users often ask about the service life of the supplier's products during the procurement process, strictly speaking, any manufacturer will not promise an accurate service life cycle for the user without any basis, because the service life of the over-current components The service life of (wear-resistant and corrosion-resistant parts) depends on many different factors. The diversity and complexity of working conditions lead to differences in the service life of materials of the same quality. However, in the early selection stage, powerful manufacturers can make reasonable selection and design for working conditions. At present, my country's power plants are mainly thermal power generation and hydropower generation. In thermal power plants, due to the large amount of coal-fired power generation, the slag or ash after coal burning needs to be removed. The slurry pump is used for ash removal. The slag is mixed After a certain amount of water is delivered to the place where the ash is piled up by the slurry pump, sometimes the slurry pump is also called the ash pump in the power plant. Thirdly, in the coal washing industry, due to different working conditions, large coal blocks and gangue are easy to clog, so the design requirements for the slurry pump are very high. In 2005, a coal washing plant under the Huaibei Mining Bureau adopted a specially designed slurry pump that was originally imported from Australia, and it has been operating normally so far, transporting large coal lumps and coal gangue without clogging, and its service life exceeds that of imported pumps.

In the field of seawater sand selection, the application of slurry pumps has gradually been recognized by customers. However, when sand is selected in seawater and sand is dredged in rivers, slurry pumps are more likely to be called sand pumps and dredging pumps. Although there are different names, they can all be referred to as slurry pumps in terms of structural characteristics and pump performance principles. Therefore, we often call it a sand pump in seawater sand selection, and it is customary to call it a dredging pump in river dredging. Although the slurry pump has a wide range of uses, the correct application is very important. Due to the limitations of the name of the slurry pump, some people who are not in this industry have misunderstood it. In fact, slurry pumps, impurity pumps, dredging pumps, dredging pumps, etc. are all in the application range of slurry pumps. In the application process of slurry pump, it is very important to pay attention to reasonable design, correct calculation and appropriate selection.

-

Keywords:

- slurry pump

Product inquiry

Fill in your telephone and email information, and we will contact you in time to solve your problems as soon as possible

Related products