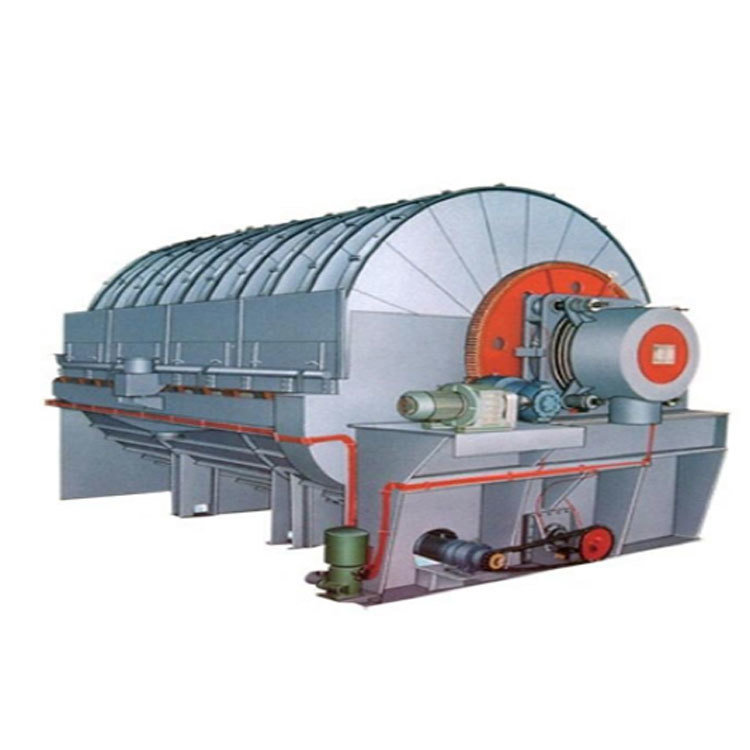

ZPG disc vacuum filter

ZPG disc vacuum filter is a new type of filter equipment developed by absorbing the advanced technology and technical improvement experience of domestic and foreign filters.

- Commodity name: ZPG disc vacuum filter

- Commodity ID: cp3002

- 产品描述

-

Product description

ZPG disc vacuum filter consists of filter disc, main shaft and gas distribution device, main shaft drive, stirring device, material guide and unloading device, filter cloth cleaning device, tank body, feeding device, centralized automatic lubrication system and other main components.

ZPG disc vacuum filter is a new type of filter equipment developed by absorbing the advanced technology and technical improvement experience of domestic and foreign filters.

Main feature

(1) The filter fan is made of high-strength plastic, which is high in strength, durable and long in life; light in weight, reduces the load of the main shaft, saves power consumption, facilitates maintenance, and reduces labor intensity of workers; the surface is smooth, and the filtrate groove is herringbone , the channel is smooth, the liquid and gas are unimpeded, and the filtrate has a large passing capacity.

(2) The filter disc is composed of 20 filter fans, and the fan angle is 18°. Reducing the fan angle can effectively make all points on the fan surface in similar working conditions and improve the dehydration effect; the filter disc adopts a ring clamp slideway And anti-swing skid, so that the plate surface is flat, the deflection is small during operation, and the cake removal rate can be effectively improved.

(3) The main shaft adopts steel pipe welding structure, 20 filter tubes are distributed in a ring shape, and the live pressure is on the circumference of the main shaft for easy maintenance; the filtrate pipeline and distribution head have large passing capacity and low resistance, and the drying area of the static disc at both ends is slightly different. It can accelerate the discharge of residual filtrate in the filtrate pipe; the main shaft is driven by a speed-regulating motor, which realizes stepless speed regulation and is suitable for a wide range of materials.

(4) A paddle-type stirring device is provided at the lower part of the tank body, the stirring shaft is parallel to the main shaft, and the paddles on the stirring shaft continuously stir the ore pulp between the filter discs. The drive of the stirring shaft is composed of a speed-regulating motor, a cycloidal pinwheel reducer, and a chain drive. The stirring speed ranges from 0 to 110r/min to realize automatic variable speed stirring to meet the filtering requirements of different materials. There are water-sealed combined sealing devices at both ends of the stirring shaft, and a certain pressure of water is injected during work to ensure a good sealing effect.

(5) Automatic centralized lubrication is adopted, and a multi-point dry oil pump regularly and automatically lubricates the lubrication points of the equipment to ensure the normal operation of each working part and reduce wear and tear.

(6) The whole machine is controlled by a programmable controller, and the console has an analog display screen, which is uniformly controlled by a 32-point programmable controller, including the start and stop of lubrication, spindle, stirring and other motors: automatic lubrication, automatic speed change for stirring , Liquid level manual and automatic control; motor overload and liquid level limit alarm; display screen can display the operation status of each component at any time.The filter disc of the ZPG disc vacuum filter is driven by a speed-regulating motor through the transmission of the reducer and the open gear pair, so that it rotates at a certain speed in the slurry tank with a certain liquid level. When a filter fan of the filter disc enters the filter adsorption area, with the help of the vacuum pump, a pressure difference is formed on both sides of the filter cloth, so that the solid material is adsorbed on the filter cloth and enters the dehydration area. Under the action of suction, the water is continuously separated from the filter cake and further discharged from the filter tube and distribution head. After entering the unloading area, the filter cake falls from the filter fan up and down into the discharge trough under the action of back blowing and scraper, and is transported away by the ore-collecting belt conveyor. The whole operation project is carried out continuously. The many advantages of ZPG disc vacuum filter make it rapidly applied and popularized in black mines

-

Keywords:

- disc vacuum filter

Product inquiry

Fill in your telephone and email information, and we will contact you in time to solve your problems as soon as possible

Related products