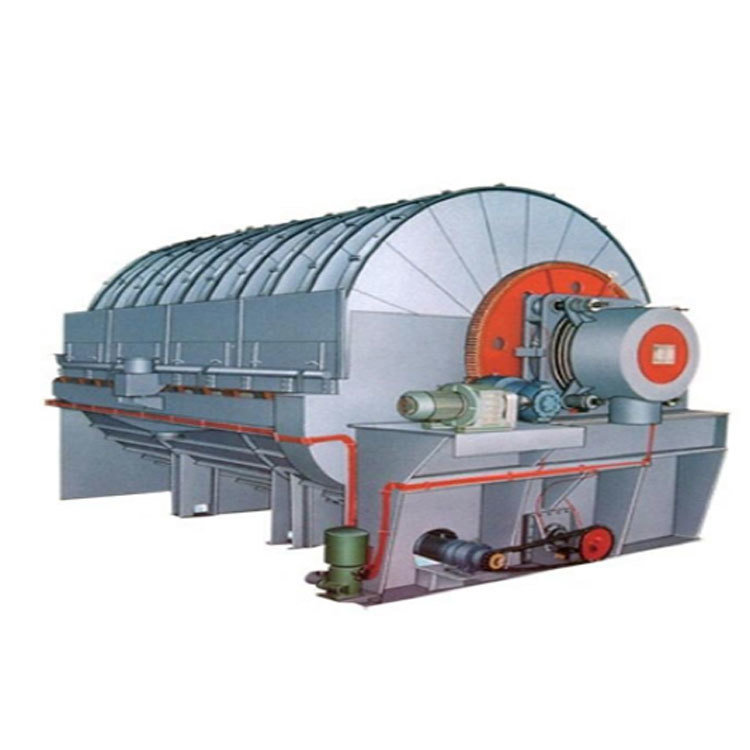

Filter press

Filter press is a commonly used solid-liquid separation equipment. It was used in chemical production in the early 18th century and is still widely used in chemical, pharmaceutical, metallurgy, dyestuff, food, brewing, ceramics, and environmental protection industries.

- Commodity name: Filter press

- Commodity ID: cp4100

- 产品描述

-

Product description

Filter press is a commonly used solid-liquid separation equipment. It was used in chemical production in the early 18th century and is still widely used in chemical, pharmaceutical, metallurgy, dyestuff, food, brewing, ceramics, and environmental protection industries.

A machine that applies mechanical force to one side of the filter medium to achieve filtration. Commonly used are "chamber pressure filter" and "belt pressure filter".

Filter press equipment is divided into box filter press equipment, plate and frame filter press equipment, belt filter press equipment, vertical filter press equipment, diaphragm press filter press equipment, etc.;

Component

The structure of filter press equipment consists of three parts:

1. Rack

The frame is the basic part of the filter press equipment. The two ends are the thrust plate and the compression head. The girders on both sides connect the two. The girder is used to support the filter plate, filter frame and compression plate. In order to meet high hygiene requirements, the frame needs to be covered with stainless steel. The stainless steel cladding technology of Hangzhou Gent can be used as a reference, and its quality can meet the needs of European customers.

A. Thrust plate: It is connected with the support to place one end of the filter press equipment on the foundation. The middle of the thrust plate of the van filter press equipment is the feeding hole, and there are four holes at the four corners. The upper two The hole in the corner is the inlet of washing liquid or compressed gas, and the bottom two corners are the outlet (undercurrent structure or filtrate outlet)

B, B. Compression plate: used to compress the filter plate and filter frame, and the rollers on both sides are used to support the compression plate to roll on the track of the girder.

C. Girder: It is a load-bearing component. According to the anti-corrosion requirements of the use environment, it can be coated with rigid polyvinyl chloride, polypropylene, stainless steel or new anti-corrosion coatings.2. Compression mechanism

Manual pressing, mechanical pressing, hydraulic pressing.

A. Manual compression: the filter plate is compressed by pushing the compression plate with a screw mechanical jack.

B. Mechanical compression: The compression mechanism is composed of a motor (equipped with an advanced overload protector), a reducer, a gear pair, a screw rod and a fixed nut. When pressing, the motor rotates forward, drives the reducer and gear pair, makes the screw rotate in the fixed nut, and pushes the pressing plate to compress the filter plate and filter frame. When the pressing force is getting bigger and bigger, the load current of the motor will increase until it reaches the moisture content of the electric cake set by the protector.

When the current value reaches the maximum pressing force, the motor cuts off the power supply and stops rotating. Since the screw rod and the fixed nut have a reliable self-locking helix angle, the pressing state during the working process can be reliably guaranteed. When returning, the motor reverses , when the pressing block on the pressing plate touches the travel switch, it returns to stop.

C. Hydraulic compression: The hydraulic compression mechanism consists of a hydraulic station, an oil cylinder, a piston, a piston rod, and the structure of a Havran card hydraulic station connected to a piston rod and a compression plate: a motor, an oil pump, and an overflow valve ( Regulating pressure) reversing valve, pressure gauge, oil circuit, fuel tank. When the hydraulic pressing machine is pressing, the hydraulic station supplies high-pressure oil, and the element chamber composed of the oil cylinder and the piston is filled with oil. When the pressure is greater than the frictional resistance of the pressing plate, the pressing plate slowly compresses the filter plate. When the tightening force reaches the pressure value set by the relief valve (displayed by the pointer of the pressure gauge), the filter plate, filter frame (plate-frame type) or filter plate (box type) is compressed, and the relief valve begins to unload. , cut off the motor power supply, the pressing action is completed, when returning, the reversing valve changes direction, and the pressure oil enters the rod cavity of the oil cylinder. When the oil pressure can overcome the friction resistance of the pressing plate, the pressing plate starts to retreat. When the hydraulic pressing is automatic pressure maintaining, the pressing force is controlled by the electric contact pressure gauge. Set the upper limit pointer and lower limit pointer of the pressure gauge to the value required by the process. When the pressing force reaches the upper limit of the pressure gauge, the power supply Cut off, the oil pump stops power supply, and the pressure force drops due to the possible internal and external leakage of the oil circuit system. When it drops to the lower limit pointer of the pressure gauge, the power is turned on, and the oil pump starts to supply oil. When the pressure reaches the upper limit, the power is cut off. The oil pump stops supplying oil, so that the cycle can achieve the effect of ensuring the pressing force in the process of filtering materials.3. Filtration mechanism

The filter mechanism is composed of a filter plate, a filter frame, a filter cloth, and a squeeze diaphragm. Both sides of the filter plate are covered by filter cloth. When a squeeze diaphragm is required, a set of filter plates is composed of a diaphragm plate and a side plate. The two sides of the base plate of the diaphragm plate are covered with rubber diaphragms, the outside of the diaphragm is covered with filter cloth, and the side plates are ordinary filter plates. The material enters each filter chamber from the feed hole on the thrust plate, and the solid particles are trapped in the filter chamber because the particle size is larger than the pore size of the filter medium (filter cloth), and the filtrate flows out from the outlet hole under the filter plate. When the filter cake needs to be squeezed dry, in addition to pressing with a diaphragm, compressed air or steam can also be used to pass through the washing port, and the airflow will wash away the water in the filter cake to reduce the moisture content of the filter cake.

-

Keywords:

- Filter press

Product inquiry

Fill in your telephone and email information, and we will contact you in time to solve your problems as soon as possible

Related products